Document Center

Deep UV LED

Product trends

Establishment of product document library on February 15, 2020

March 17, 2020 new 3MW monochromatic lamp beads on the market

On June 15, 2020, the name of deep purple scientific and technological products will be adjusted significantly

August 17, 2020: Shenzhen purple Technology Co crystal lamp bead products on the market

Product introduction

quick get start

Practical cases

exception handling

common questions

What is the effective irradiation distance of uvc-led?

Does deep UV uvc-led produce ozone during operation?

Does UVC have harm to human body and how to protect it?

How to choose the window material for deep UV LED applications?

Can deep ultraviolet decompose formaldehyde?

How far is the propagation distance of uvc-led in water?

Effective sterilization range of deep UV uvc-led?

How to test the luminous angle of lamp bead quickly?

Five factors affecting the disinfection or sterilization effect of deep UV LED

Why does uvc-led have color difference?

Is uvc-led driven by constant voltage or constant current?

What is deep UV LED?

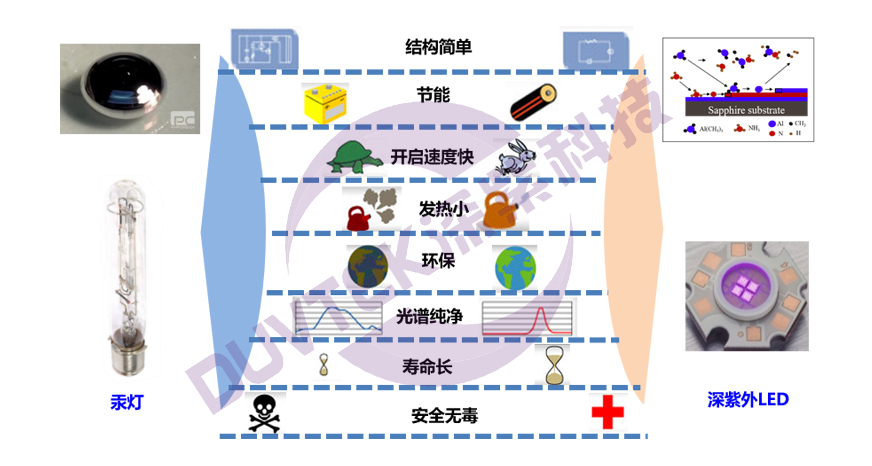

At present, the emergence of deep ultraviolet LED is a rigid substitute for mercury lamp. The traditional ultraviolet light source usually uses mercury vapor discharge to generate ultraviolet light by using the excited state of mercury. It has many defects, such as high power consumption, large calorific value, short service life, slow reaction and potential safety hazard. The emerging deep ultraviolet light source uses the LED luminous principle, which is called deep ultraviolet LED.

Compared with the traditional mercury lamp, the new type of deep ultraviolet LED has many advantages. First of all, deep UV LED has a simple structure, no fragile glass shell, portable, shock resistant, working voltage is only a few volts, and no complex drive circuit is required. Secondly, deep UV LED can be turned on quickly without preheating, which is very suitable for rapid detection, high-speed communication and other applications. Compared with the traditional mercury lamp multi spectral line emission characteristics, deep UV LED emission peak is single, and the emission wavelength is continuously adjustable. In terms of environmental protection and energy saving, deep UV LED materials do not contain harmful substances to the environment and are environmentally friendly. At the same time, compared with traditional UV light sources, deep UV LED can save up to 70% of energy and meet the requirements of European Union (RoHS) on harmful substances. Finally, the life span of deep UV LED has reached more than 5000 hours, which is longer than that of mercury lamp. Therefore, on the one hand, it is an inevitable trend of social development to vigorously promote the research and development of deep ultraviolet led to replace the traditional ultraviolet light source. On the other hand, the application potential of deep ultraviolet LED will far exceed that of mercury lamp and can penetrate into more application fields.

On January 19, 2013, the United Nations Environment Programme (UNEP) adopted the Minamata convention, an international convention aimed at controlling and reducing mercury emissions worldwide. With the formal entry into force of Minamata convention in 2020, the production of UV mercury lamps will be banned, and UVLED light sources are bound to replace UV mercury light sources on a large scale. Therefore, the use of UVLED light source must be the trend.

With the continuous development of semiconductor LED industry, the application of deep ultraviolet LED in industry, household and military fields is deepening, and the application fields are expanding. The urgent demand for low-cost and high-power deep ultraviolet LED in water purification, sterilization, medical and health, photocatalysis, phototherapy and other fields is becoming more and more obvious. And with the general lighting field reshuffle in 2016, the focus of major enterprises in 2017 began to shift to the subdivision field. It is estimated that the market output value of UVC led sterilization and purification applications will reach 28 million US dollars in 2016 and 257 million US dollars in 2021, with an annual compound growth rate of 56%. However, the deep UV LED products have a high technical threshold, and the epitaxy, chip, packaging and market acceptance are facing many challenges.