Uvc-led application design document

Application of uvc-ledDesign documents

Version 1.0 2018.04.08

1. Biosafety

Although deep ultraviolet light can sterilize effectively, it is also harmful to human body. Excessive UV irradiation can lead to mass necrosis or mutation of human cells, which is the main cause of skin cancer and cataract. If the daily ultraviolet disinfection cabinet, ultraviolet air purifier and ultraviolet water purifier are not used properly, there is a risk of "UV leakage". The danger is that because UV light is not visible, it is difficult for ordinary people to know whether there is a leak in the short term, but it is too late to find out. In 2016, there was a tragedy in a kindergarten in Hangzhou that, due to the negligence of the staff, the UV disinfection lamp was forgotten to turn off when someone was there, resulting in serious visual impairment of many children in the class.

Please refer to the national standard gb21551.3-2010 for the UV safety specification of household appliances. The UV intensity is ≤ 5 μ w / cm2 at 30cm around the appliance

2. Lens angle

The light angle can be adjusted by adjusting the LED packaging lens. Narrow angles allow high intensity light to be obtained in smaller areas. This type of package is usually used when focusing light directly into the instrument. Flat window package has wider radiation. In fact, the narrow corner spherical lens can keep the components in the instrument to a minimum, while the plane window can improve the design flexibility.

3. Driving current

Optimizing the driving current requires the designer to balance the life requirements of the optical output and the application. Driving LEDs at less than rated current reduces light output, but also increases the life of the light source. In applications requiring high LED output power, some end users choose to operate LEDs at a current higher than the data sheet specification. Increasing the drive current in this way can increase the optical output, but also lead to some performance risks.

4. Duty cycle drive

Overheating is a common problem, which can have a negative impact on the light output and life of LED. Due to the instant switch function of LED, the LED can be turned on and off quickly in a periodic manner. Fluorescent applications usually require higher light output, usually using pulse mode (duty cycle) to increase LED current more safely. Duty cycle refers to the proportion of power on time relative to the total time in a pulse cycle. For example, an LED operating at 50% duty cycle takes exactly half the time to turn off and half to turn on. The figure below shows the normalized optical output at various driving currents and duty cycles.

Here we see the effect of different duty ratios on the normalized light output, and the turn-on time is constant at 500 μ s. The normalized power is the relative optical output power relative to the maximum rated operating current of 100mA (with appropriate heat sink).

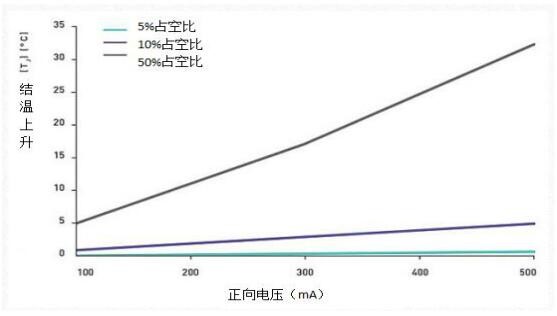

Operating LED with high current will affect the junction temperature of LED, which will affect the lifetime and light output. The optimized duty cycle can minimize the influence of driving current on junction temperature, thus maintaining the performance of LED. The above figure shows the effect of duty cycle on maintaining LED junction temperature. By working at 5% duty cycle, the light output can be more than three times, and the effect on junction temperature is minimal.

The diagram shows the effect of different duty ratios on junction temperature, and the opening time remains constant at 500 μ s.

Overheating will have a negative impact on the light output and service life of LED. In the long run, this heat can reduce the life of LEDs. Compared with long wavelength LED, the ratio of energy to heat is larger, so thermal management is very important when designing UVC led. Proper thermal management keeps junction temperature at the low temperature required for a given application and maintains led performance. In addition to passive and active cooling methods, the selected PCB can also achieve better heat dissipation.

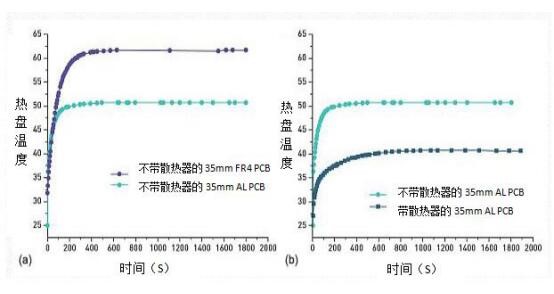

Compare the hot plate temperature of FR4 and aluminum core PCB without radiator (a); compare the hot plate temperature of aluminum core PCB with and without radiator (b)

FR4 is one of the most commonly used PCB materials because of its relatively low cost but low thermal conductivity. In the system with high thermal load, metal core PCB has better thermal conductivity and is a better choice. With the increase of heat dissipation demand, designers usually tend to increase PCB area and add heat sink to achieve good heat management. &If further cooling is needed, designers can adopt more active cooling technology.

The bacteria in the radiator / evaporator of air conditioner exceed the standard and become a potential safety hazard

Technology sharing · 2018年10月04日 · 300次瀏覽

Hubei Daily: Chen Changqing, founder of the company

media coverage · 2019年04月01日 · 1171次瀏覽

Group company youweixin was selected as a national specialized and new "small giant" enterprise

Company news · 2022年08月16日 · 250次瀏覽

Vantage dishwasher takes the lead in introducing UVC sterilization technology to solve the problem of tableware bacteria breeding

Industry information · 2018年10月15日 · 421次瀏覽

Youweixin has won the first prize in the Wuhan Science and Technology Innovation Competition!

Company news · 01月15日 · 47次瀏覽

Three questions lead you to understand the market of ultra violet uvc-led

Technology sharing · 2018年10月20日 · 849次瀏覽

Distinguished youth, Changjiang Scholar, Professor Lu Hai of Nanjing University and his party visited our company

Company news · 2018年04月25日 · 606次瀏覽

The technical director of deep purple technology market was invited to participate in the UV LED Changzhi International Conference and Changzhi LED production

Company news · 2019年05月31日 · 310次瀏覽