Document Center

Deep UV LED

Product trends

Establishment of product document library on February 15, 2020

March 17, 2020 new 3MW monochromatic lamp beads on the market

On June 15, 2020, the name of deep purple scientific and technological products will be adjusted significantly

August 17, 2020: Shenzhen purple Technology Co crystal lamp bead products on the market

Product introduction

quick get start

Practical cases

exception handling

common questions

What is the effective irradiation distance of uvc-led?

Does deep UV uvc-led produce ozone during operation?

Does UVC have harm to human body and how to protect it?

How to choose the window material for deep UV LED applications?

Can deep ultraviolet decompose formaldehyde?

How far is the propagation distance of uvc-led in water?

Effective sterilization range of deep UV uvc-led?

How to test the luminous angle of lamp bead quickly?

Five factors affecting the disinfection or sterilization effect of deep UV LED

Why does uvc-led have color difference?

Is uvc-led driven by constant voltage or constant current?

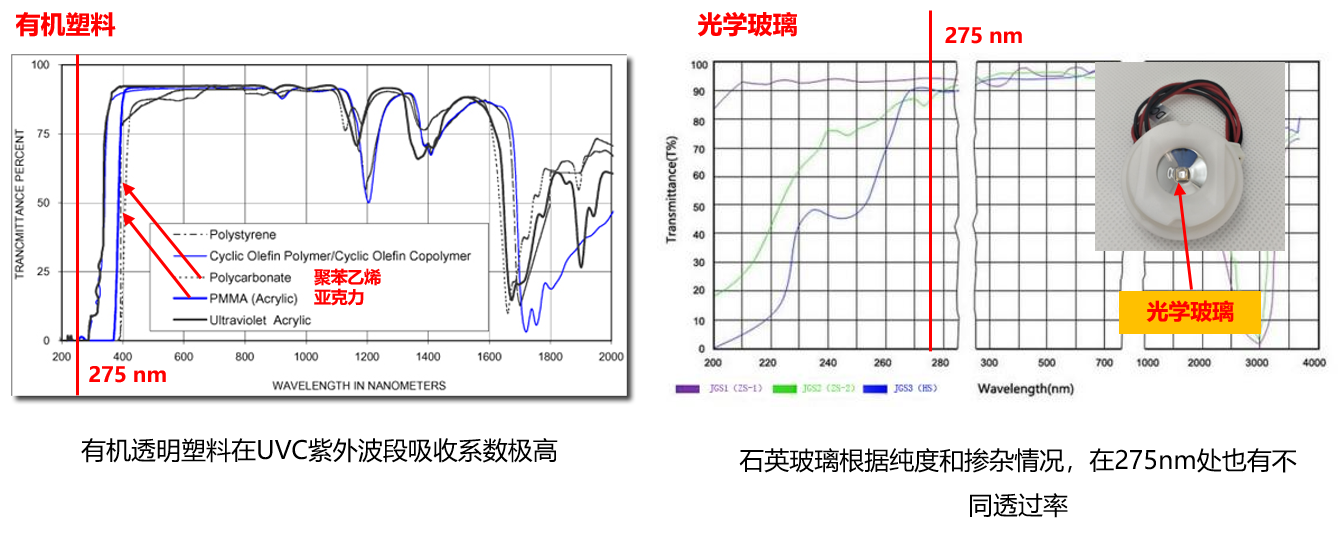

How to choose the window material for deep UV LED applications?

During the scheme design, the customer mistakenly thought that the transparent plastic such as acrylic, which is common in visible light scheme design, can also be used as the light window of uvc-led, and the sterilization effect is zero. This is not uncommon. Using the concept of bond energy, the absorption coefficients of C-H and C-O bonds in UVC and UVB are very high, so thin plastics can absorb almost all of the deep ultraviolet. The absorption edge of ordinary polystyrene and acrylic is about 385nm, and the transmittance at 275nm is equal to zero.

What kind of material should be used to make deep UV LED light window? Sapphire is the substrate of deep ultraviolet LED, and also the light surface of chip, so it can be used as light window, but the material and processing cost are high. There are many types of quartz, three common optical glass, jgs123. It is recommended that 275nm uvc-led can use jgs2 quartz, 265nm or even below led, JGS1 quartz or sapphire is required. This also applies to the lens material of lamp bead package.

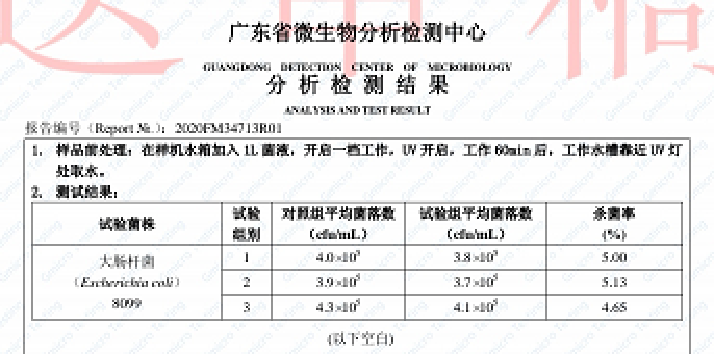

The following figure shows the sterilization test report of the customer's products, and the sterilization rate is very low.

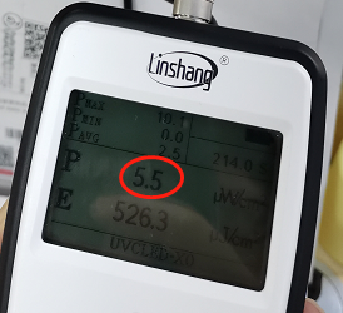

After receiving the customer's feedback, our FAE first tests the optical power density of the customer's products with an optical power density meter, as shown in the figure:

After testing, it was found that the optical power density was very low. Looking at the light transmission window, the customer used acrylic plate, resulting in low sterilization rate. So what kind of material should be used to make the light window of deep UV LED? Sapphire is the substrate of deep UV LED and the light emitting surface of the chip, so it can be used as a light window, but the material and processing cost are high. There are many kinds of quartz. There are three common types of optical glass, JGS1 / jgs2 / jgs3. It is recommended that the quartz of jgs2 specification can be used for 275nm uvc-led, and the LED of 265nm or below, and JGS1 quartz or sapphire should be used.